Kitec plumbing systems were once promoted as a modern alternative to traditional piping. Installed widely from the mid 1990s through the early 2000s, these pipes were marketed for flexibility, ease of installation, and corrosion resistance. Over time, widespread failures revealed serious flaws that now place many homes at risk. Understanding why kitec plumbing is problematic and how replacement typically works allows property owners to address exposure before damage becomes disruptive and expensive.

Unlike visible plumbing components, Kitec piping is usually hidden behind walls, beneath floors, or above ceilings. This concealment allows deterioration to progress quietly. By the time symptoms appear, damage has often already occurred, making professional assessment and planning essential.

What Kitec plumbing pipes are and where they are found

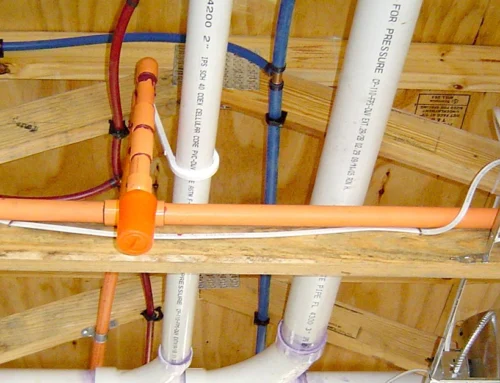

Kitec plumbing systems use flexible plastic pipes reinforced with an internal aluminum layer. Hot water lines are typically orange, while cold water lines are blue. Brass fittings connect the system throughout the structure.

These systems were installed in a wide range of residential properties, including single family homes, townhomes, and multi unit buildings. Because the pipes are concealed, many homeowners remain unaware of their presence until problems surface.

- Commonly found in homes built or renovated between the mid 1990s and early 2000s

- Installed behind walls, under slabs, and within ceiling cavities

- Connected using brass fittings vulnerable to internal corrosion

- Difficult to confirm without professional inspection

The hidden nature of kitec plumbing increases the risk of unexpected failure. Without proactive identification, leaks often occur suddenly rather than gradually.

Why Kitec plumbing systems fail over time

The primary risks associated with Kitec plumbing stem from material interactions with water, heat, and pressure. These factors combine to weaken both the pipes and their fittings from the inside out.

- Brass fittings corrode internally through dezincification

- Aluminum layers react to temperature fluctuations, creating stress

- Plastic piping degrades more rapidly when exposed to sustained heat

- Mineral buildup narrows the pipe diameter and increases internal pressure

Seasonal conditions can accelerate this deterioration. Pressure changes during colder months place additional strain on already weakened systems. Guidance on cold-weather plumbing risks highlights how vulnerable piping materials are more likely to fail when temperatures fluctuate and water demand shifts.

These failures rarely present early warnings. Instead, they often result in sudden leaks behind walls or beneath flooring, leading to extensive water damage before detection.

Signs that indicate Kitec plumbing risk

Although Kitec plumbing issues are frequently hidden, certain indicators may suggest elevated risk. These signs do not always appear before failure, but when present, they should prompt immediate professional evaluation.

- Reduced water pressure across multiple fixtures

- Cloudy or discolored water output

- Unexplained increases in water usage or utility bills

- Damp spots, staining, or bubbling paint on walls or ceilings

Because visible symptoms are unreliable, professional assessment focuses on identifying system materials and evaluating overall exposure rather than waiting for failure. Homes with Kitec plumbing are also more susceptible during colder seasons, when leaks often escalate into serious events. Awareness of winter plumbing warning signs reinforces why early action is critical.

How Kitec plumbing replacement typically works

Replacing Kitec plumbing is a structured process designed to remove long term risk rather than temporarily manage symptoms. Professional replacement focuses on full system removal, as leaving any portion of Kitec piping in place preserves failure potential.

- Identification and mapping of all Kitec pipe locations

- Strategic access planning to limit unnecessary wall or ceiling damage

- Complete removal of Kitec piping and brass fittings

- Installation of modern approved piping materials

- Pressure testing and system verification before restoration

Replacement is often completed in phases to maintain water access when possible. Once piping is updated, surfaces are restored, returning the home to normal function with improved reliability. The goal is permanent resolution rather than repeated repairs.

Why professional replacement reduces long-term risk

Kitec plumbing replacement requires more than material substitution. Proper execution depends on understanding system layout, pressure dynamics, and building structure. Professional oversight ensures replacement meets current standards and avoids secondary issues such as improper routing or pressure imbalance.

Delaying replacement or attempting partial solutions often increases overall cost. Water damage repairs, mold remediation, and structural restoration frequently exceed the expense of proactive replacement. Addressing the issue comprehensively also improves property value and reduces insurance complications tied to known plumbing risks.

Replacing Kitec plumbing eliminates uncertainty and restores confidence in the system. With modern materials in place, homes are better protected against leaks, seasonal stress, and unexpected disruptions.

Replacing uncertainty with long term protection

Kitec plumbing systems present documented risks that worsen with time. For expert evaluation and professional replacement planning, contact New Flow Plumbing.